Mobility

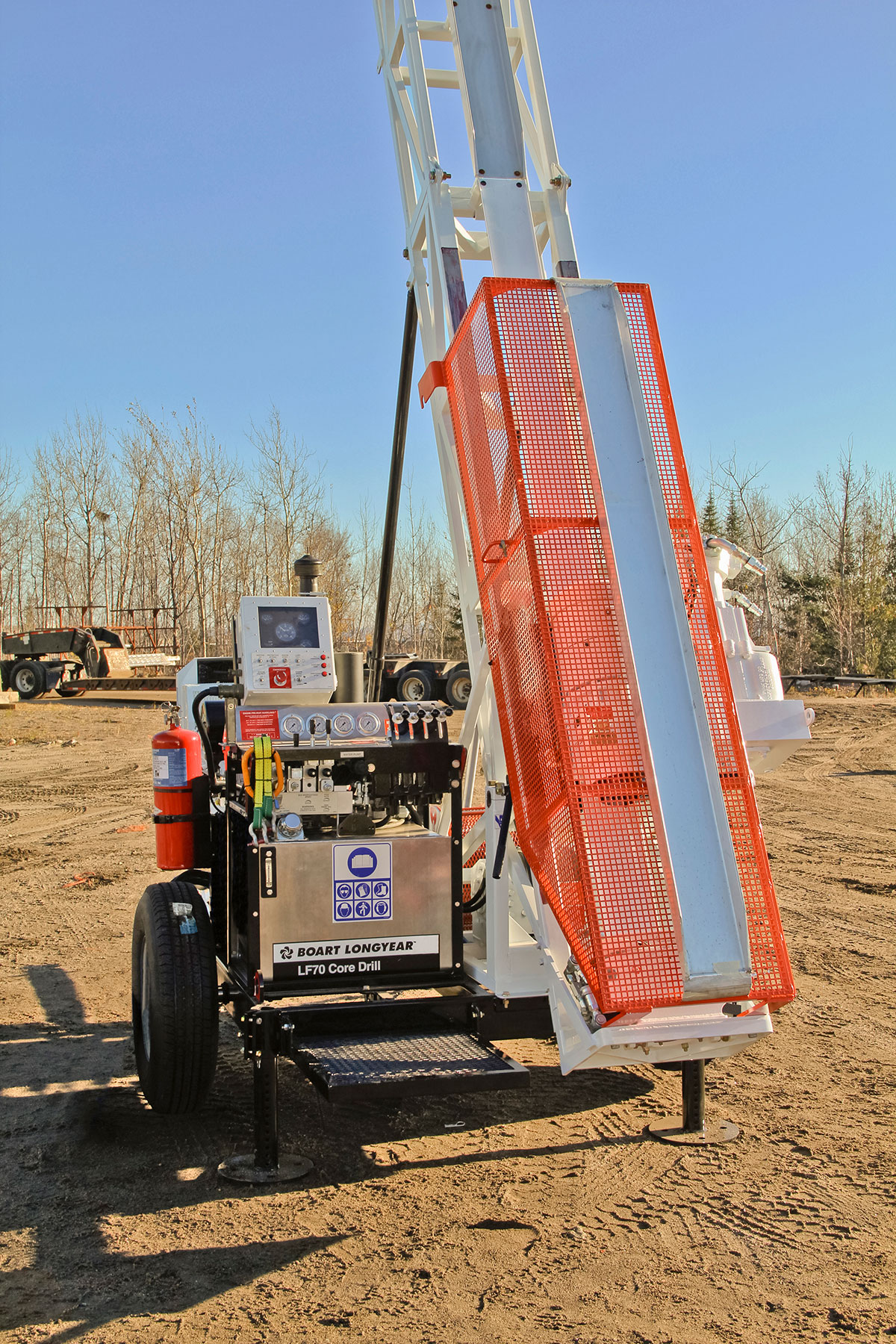

The LF™70 modular design consists of seven sections that are heliportable for reaching remote locations. This drill reduces downtime when mobilizing between sites and significantly decreases the environmental impact to a drill site.

Modular Design

With just seven components, it takes less than one hour to pull down the rig and the same amount of time to reassemble it.

Lightweight

Special attention was given to the overall weight and dimension of the drill’s design. Each of its seven components weigh less than 585 kg and are easily transportable by helicopter. The LF70 is ideal for drilling in confined, remote locations.

Features

1. SOLID STRUCTURAL DESIGN

Rigid design provides superior performance and reliability even under the toughest conditions.

2. NITRO CHUCK™

The patented nitrogen gas spring jaws with hydraulic open/spring-close function ensures a fail-safe operation.

3. SIMPLE HYDRAULIC DESIGN

Direct-coupled hydraulic pumps with a PTO-driven auxiliary pump allow for easy maintenance.

4. FLYABLE

The LF™70 easily breaks down into seven flyable modules with a maximum weight of 585 kg (1,290 lbs).

5. PQ ROTATION UNIT

Four-speed transmission delivers high torque when needed, and high speed for diamond drilling.

6. SELF-CONTAINED OPERATOR PANEL

The simple hydraulic system is easy to operate and maintain while lift-to-shift levers provide additional operator safety

| Specifications | Metric | U.S. |

| Depth Capacity | 895 (NRQ W-Wall) | 2,936 (NRQ W-Wall) |

| Drill Rod Size | BQ to PQ | |

| Main Hoist | 53.4 kN | 12,000 lb |

| Pull Force | 62.9 kN | 12,137 lb |

| Rod Pull | 6 m | 20 ft |

| Engine | Cummins® QSB 4.5 L | |

| Engine Power | 110 kW | 148 hp |

DOWNLOAD FULL SPREADSHEET (XLS)

Specifications"]