SuRFACE Roller latch™ QUICK DESCENT™ HEAD ASSEMBLY AND OVERSHOT

Drillers regularly deal with several challenges when retrieving a core barrel, partial trips, stuck tubes, and spearhead failures. Tripping for a stuck inner tube is a costly process, and it increases the opportunity for injury. We created the original wireline technology used throughout the industry, and we’ve focused our experience on reinventing core retrieval.

With innovative, patented technology, the surface Roller Latch™ Quick Descent™ head assembly and overshot is a simple, easy-to-use system that improves performance, productivity, and safety.

Our newest addition to the exploration drilling industry is the surface Roller Latch™ Quick Descent™ head assembly and overshot. Together, they are safer, more productive, and designed to last longer than any head and overshot system in use today.

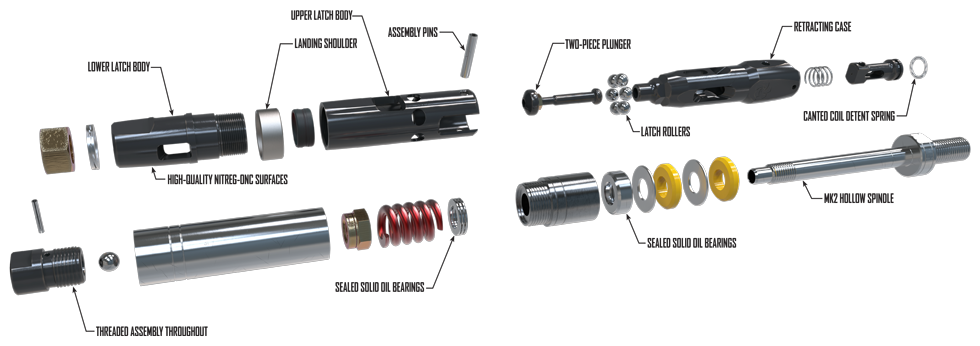

HEAD ASSEMBLY ADVANCES AND FEATURES

ROLLER LATCH TECHNOLOGY - STRONGER, MORE RELIABLE LATCHING ELIMINATES DRIVE KEYS AND TANGS

Before Roller Latch™ technology, mechanical elements commonly known as ‘drive keys’ or ‘tangs’ were employed to drive the head assembly with the rod string in order to eliminate movement and wear between the latches and the locking coupling and between the landing shoulder and outer tube landing ring.

SELF-LOCKING FEATURE

Roller Latch™ technology includes a self-locking feature where the latches are driven rotationally by the rod string. This ensures the head assembly rotates with the rod string, minimizing wear of rollers, landing shoulders, and outer tube landing rings.

FREE FLOW DESIGN WITH LATCH DETENT

A canted coil spring – mounted on the extension – snaps into grooves in the retracting case interior. The detent greatly increases speed by reducing latch drag and automatically re-engages when the head is retracted; there is no driller intervention.

MK2 HOLLOW SPINDLE

The hollow spindle allows for increased tripping speed while the check valve has been relocated to the inner tube cap, reducing pressure drag.

The relocated check valve also allows stretching of the core break spring to check rod seals.

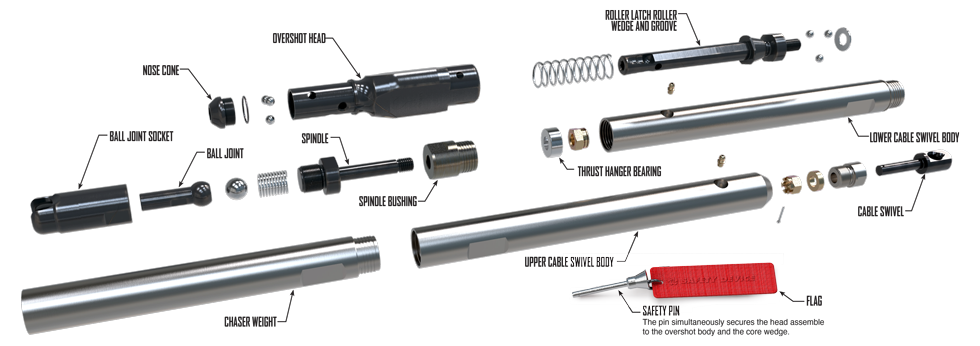

OVERSHOT FEATURES AND FUNCTIONS

Elimination of Jar Staff

The Roller Latch Overshot features a brand-new release system with a heavier sleeve, allowing the jar staff to be eliminated.

SOCKET ADAPTER & SAFETY PIN

Designed to upgrade existing head assemblies, the spearhead is completely replaced by a socket in the head. The safety pin provides a secondary safety device under all conditions and does not degrade with overshot wear.

360º Degree Swivel

The new Roller Latch pivot design uses past experience to improve the handling of inner tube assemblies. Once out of the rod, inner tube assemblies need to be moved to work areas and laid flat so that the overshot can be disconnected. Having a flexible joint is critical to completing this task safely and quickly.

SAFER ROLLER LATCH TECHNOLOGY

The new overshot allows users to eliminate spearheads and lifting dogs entirely. Lifting dogs experience wear on their latching surfaces with every use, as do the spearpoints. Eventually, the surfaces wear, and the connection fails. Our patented Roller Latch design reduces the chance of release due to wear by ensuring rolling engagement and locking.

AVAILABLE ASSEMBLIES AND KITS

| Part No. | Description |

|---|---|

| 5009350 | HEAD ASSEMBLY, NQ Q/D R/L MK2 |

| 5009355 | HEAD ASSEMBLY, NQTK Q/D R/L MK2 |

| 5009360 | HEAD ASSEMBLY, HQ Q/D R/L MK2 |

| 5009660 | OVERSHOT, NQ R/L Q/D |

| 5009678 | OVERSHOT, HQ R/L Q/D |

| 5010462 | KIT, NQ R/L Q/D O/SHOT ACCESSORIES |

| 5010463 | KIT, HQ/PQ R/L Q/D O/SHOT ACCESSORIES |

| 5010355 | KIT, PQ R/L Q/D O/SHOT CONVERSION |