OPERACIÓN DE MINAS

mayo 16, 2018

A su servicio: personalización del nuevo Stopemaster ™ MDR en Canadá

Recientemente, un cliente de minería en Canadá solicitó a Boart Longyear que desarrollara un equipo de perforación móvil para resolver los problemas que enfrenta al tener que mover su equipo operativo StopeMaster ™ de forma segura y rápida a través de la mina.

Con el procedimiento actual, la plataforma StopeMaster debía ser escoltada por una pala en frente y detrás del equipo en cada movimiento. La plataforma StopeMaster es esencial en la perforación de producción en la mina, pero tarda en moverse y obstaculiza el tráfico en la rampa a medida que avanza por la mina. Este proceso le estaba costando tiempo y recursos a la mina.

Para resolver este desafío, el equipo de ingeniería de Servicios de Perforación de Boart Longyear creó un plan de varias fases para agregar funcionalidad y movilidad a los equipos StopeMaster existentes. La primera fase del plan fue diseñar y construir un equipo StopeMaster más móvil, luego pasar a la manipulación de barras manos libres y finalmente a la perforación semiautónoma.

Con la dedicación combinada de muchos empleados notables de Boart Longyear ™ en todo el mundo, el equipo comenzó a diseñar un nuevo equipo Stopemaster ™ MDR que resolvería los problemas que estaba experimentando la compañía minera.

Unas semanas antes de que se entregara el equipo MDR, representantes del grupo de trabajo de Servicios de Perforación de Boart Longyear acompañaron al equipo de preevaluación de la mina para buscar en cada rincón del prototipo para identificar proactivamente y abordar el cumplimiento de los estándares del cliente.

Para garantizar el despliegue exitoso de la nueva plataforma de perforación móvil StopeMaster MDR, un equipo especializado de Boart Longyear pasó 16 días en el lugar resolviendo todos los detalles y asegurándose de que todo estuviera funcionando bien. El equipo incluyó perforadores de percusión dedicados y un diseñador de producción sénior.

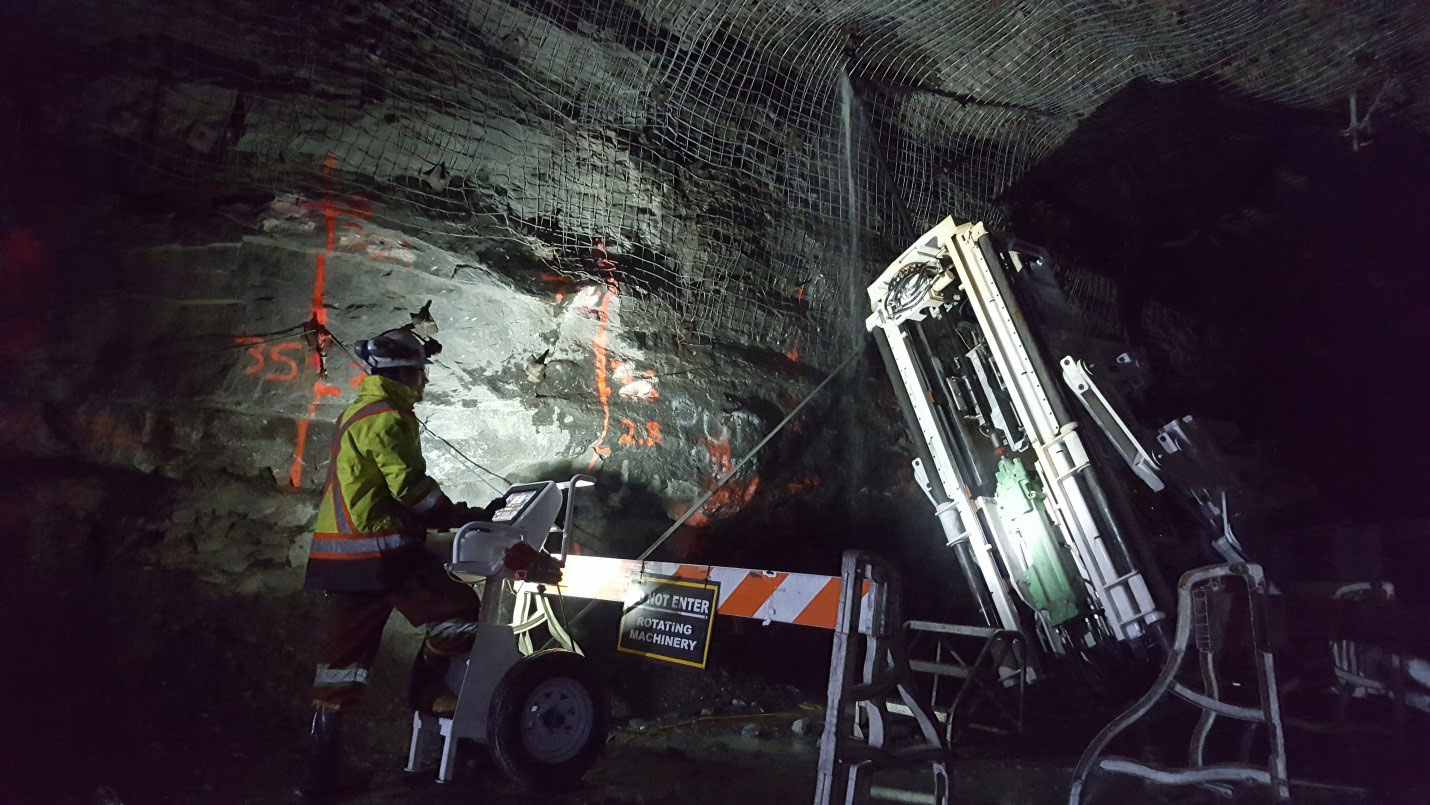

En la tarde del 10 de marzo de 2018, el primer equipo Stopemaster MDR se subió a la rampa al ingresar al portal para su despliegue inaugural en una mina en el norte de Ontario, Canadá. Poco después, colisionó con su primer hoyo.

Perforación con la nueva plataforma StopeMaster MDR

Desde el momento en que la plataforma llegó a la mina, el equipo de Boart Longyear ™ trabajó diligentemente con el cliente para abordar rápidamente cualquier inquietud nueva identificada por los revisores in situ. Durante los días subsiguientes, el equipo de perforación aprendió rápidamente las nuevas interfaces LMi: un par de joysticks, una perilla y una pantalla táctil habían reemplazado la matriz reconocible de indicadores y controles nativos de la robusta máquina StopeMaster ™.

(De izquierda a derecha) Empleados de Boart Longyear: Willie Coderre, Tyler Allin, Zane Clark, Al Portugie, James Forest, Dan Kirkey

Después de días de afinar la plataforma y ajustar el software que controlaba los aspectos de manejo de la varilla del taladro, finalmente se permitió que los perforadores perforaran. Estos entusiastas hombres cooperaron como equipo de etiqueta para completar el primer hoyo de 17 metros que rompió expectante a través de una falla de agua conocida que arrojó agua a 4 ° C sobre el taladro y los perforadores.

Configurando el MDR en su primer agujero

Luego llegó el momento de un cambio de tripulación, y un nuevo grupo de perforadores se embarcó en el proyecto. El siguiente hoyo tuvo que ser perforado en el rebaje con una cascada de refrescante agua subterránea canadiense que brotaba sin cesar en el taladro. Sin mucha queja, el perforador asignado se puso sus engrasadores y desafió obedientemente las condiciones húmedas y frías, barra tras barra. El taladro se esforzó por excavar con las últimas varillas, por lo que el perforador dedicado los jaló a todos para controlar la broca, y luego envió la sarta de perforación nuevamente. Solo más tarde se atribuyó el problema de penetración a una válvula que funcionaba mal, pero el perforador avanzó con dificultad. Con medio metro por recorrer, el turno había terminado y era hora de renunciar por el día.

Debido a los desafíos logísticos que siguieron, algunos miembros del equipo de perforación estaban, por una razón u otra, temporalmente no disponibles. Otro miembro del equipo aceptó el reto de entrenar en el nuevo ejercicio.

Con diligencia luchó a través del problema de la válvula aún sin diagnosticar para completar el último medio metro del hoyo anterior y siguió ese rendimiento completando un hoyo de 17 metros de longitud. Con el taladro en el sitio durante más de una semana en este punto, el último perforador ahora ostentaba el título "Most Meters Drilled" (perforado) para el nuevo equipo StopeMaster MDR.

Después de agonizar por la velocidad de penetración extremadamente lenta, la barra golpeadora en el trainera se partió con solo tres metros más en el agujero. El equipo reemplazó la barra de ataque y completó el obstinado agujero.

Mientras reposicionaba el taladro para el siguiente hoyo, el perforador fue capaz de identificar rápidamente una debilidad en uno de los actuadores que despliega los estabilizadores del taladro. El ejercicio se cerró nuevamente y se hizo seguro antes de que el equipo volviera a la superficie para realizar una lluvia de ideas sobre un plan para reforzar el estabilizador. Con un plan en la mano, el equipo tomó otro día de mantenimiento para ejecutar la corrección.

Con los problemas de los estabilizadores ahora resueltos, el taladro se reposicionó con éxito y comenzó otro agujero, esta vez con el equipo enfocándose en los microconductos detallados durante todo el proceso de perforación. El equipo de perforación pudo identificar y diagnosticar la válvula que se porta mal y en poco tiempo, la nueva broca recibió una pieza de repuesto. Un par de mangueras aquí, algunos pernos allí, y el control de presión de alimentación fue arrebatado del Controlador Lógico Programable (PLC) y temporalmente devuelto a las manos de un experimentado perforador de agujero largo.

Finalmente, con múltiples problemas resueltos, el equipo se unió para intentar perforar algunos metros sin problemas. Con el taladro se comportó mucho mejor, cinco hoyos se perforaron fácilmente para un total de 83 metros ese día.

Aunque inicialmente se experimentaron desafíos con el prototipo, tener el equipo de Boart Longyear disponible en el sitio significaba que podían adaptarse, ajustar y corregir rápidamente cualquier problema. Debido a su dedicado trabajo en equipo, la tripulación pudo cumplir con la petición del cliente de actualizar el StopeMaster a una plataforma de perforación móvil con manejo de varilla y perforación semiautónoma.

El equipo StopeMaster MDR recientemente comisionado resolvió los problemas de mover el StopeMaster, haciendo que los movimientos desde el tabique hasta el rebaje sean más rápidos y requiriendo menos tiempo y recursos de la mina. El equipo StopeMaster MDR también es más seguro con capacidades de manejo de barras y perforación semiautónoma con un nuevo panel de control LMi que controla tanto el manipulador de barras como el equipo StopeMaster MDR.

CAPACIDADES DE LOS SERVICIOS DE PERFORACIÓN

Obtenga más información acerca de las capacidades, la flota, los programas de seguridad y los métodos de perforación de Boart Longyear Drilling Services al descargar esta Descripción general de los servicios de perforación.

DESCARGAR

[pardot-form height="770" id="2928" title="Download Drilling Services Capabilities PDF"]

Permiso para los medios: Boart Longyear le otorga el permiso inmediato para volver a publicar este artículo. Le solicitamos que cite a Boart Longyear como fuente y proporcione un enlace de regreso donde corresponda.