EXPLORATION

18 avril 2019

Lisez-le et pleurez - Boart Longyear va en profondeur

Innovation de pointe et impressionnant personnel de forage atteint une profondeur presque record

La division de carottage de services de forage Boart Longyear ™ a achevé un forage d'une profondeur quasi record de 3200 mètres en Amérique du Nord à la fin de l'année dernière. En utilisant le matériel de forage et l'outillage les plus récents et les plus performants de Boart Longyear, l'équipe a achevé le projet dans les délais et le budget impartis, tout en veillant à la sécurité de tous.

L’équipe de forage du carottage de surface de Drilling Services a utilisé le puissant LF ™ 350e ainsi que les nouvelles tiges de carottage filaires brevetées XQ ™ avec W-Wall, ainsi que les nouveaux forets diamantés Longyear ™ pour percer avec succès un angle de 65 degrés par rapport aux exigences du client profondeur - qui était presque 10 500 pieds (3200 mètres). Un exploit en soi, le projet a permis des gains de productivité mesurables et a prouvé que les dernières plates-formes et l’outillage Boart Longyear font une réelle différence sur le terrain.

Grâce aux caractéristiques innovantes de la foreuse, combinées aux tiges de carottage les plus profondes du marché et aux mèches les plus rapides et les plus lisses, le succès du projet a également été attribué au talent, à l'expérience et au savoir-faire technique de l'équipe.

LF350e

Boart Longyear a combiné la technologie éprouvée de ses machines de carottage de surface les plus populaires pour créer le puissant LF ™ 350e. La pince de rupture de tige est un dispositif de rupture hydraulique, ce qui signifie qu'aucune clé n'est sous tension. La pince à pied tourne pour casser les joints de tige situés entre la pince à pied et la pince de rupture de tige. La plate-forme comporte également une cabine de foreuse chauffée et climatisée pour protéger l'opérateur des éléments et des dangers en hauteur. En utilisant la communication par bus CAN et la programmation automate, toutes les fonctions du LF350e sont contrôlées électroniquement. Le «e» dans LF350e fait référence au système de contrôle entièrement électronique. La plate-forme est conçue de manière ergonomique pour réduire la fatigue et le stress du foreur et de l’assistant. Le LF350e a une vitesse filaire ajustable pour pouvoir régler le tir en surpoids, puis tirer sur le tube, ce qui permet une approche plus sécurisée sans intervention de l'utilisateur. Cette conception ergonomique à sens unique contribue à réduire la fatigue avec cette foreuse. La beauté du modèle commercial de Boart Longyear, qui comprend à la fois des services de forage sous contrat et une entreprise de produits de forage, est l’accès immédiat aux informations en retour, non filtrées, des foreurs du secteur. Foreuses conçues pour les foreurs.

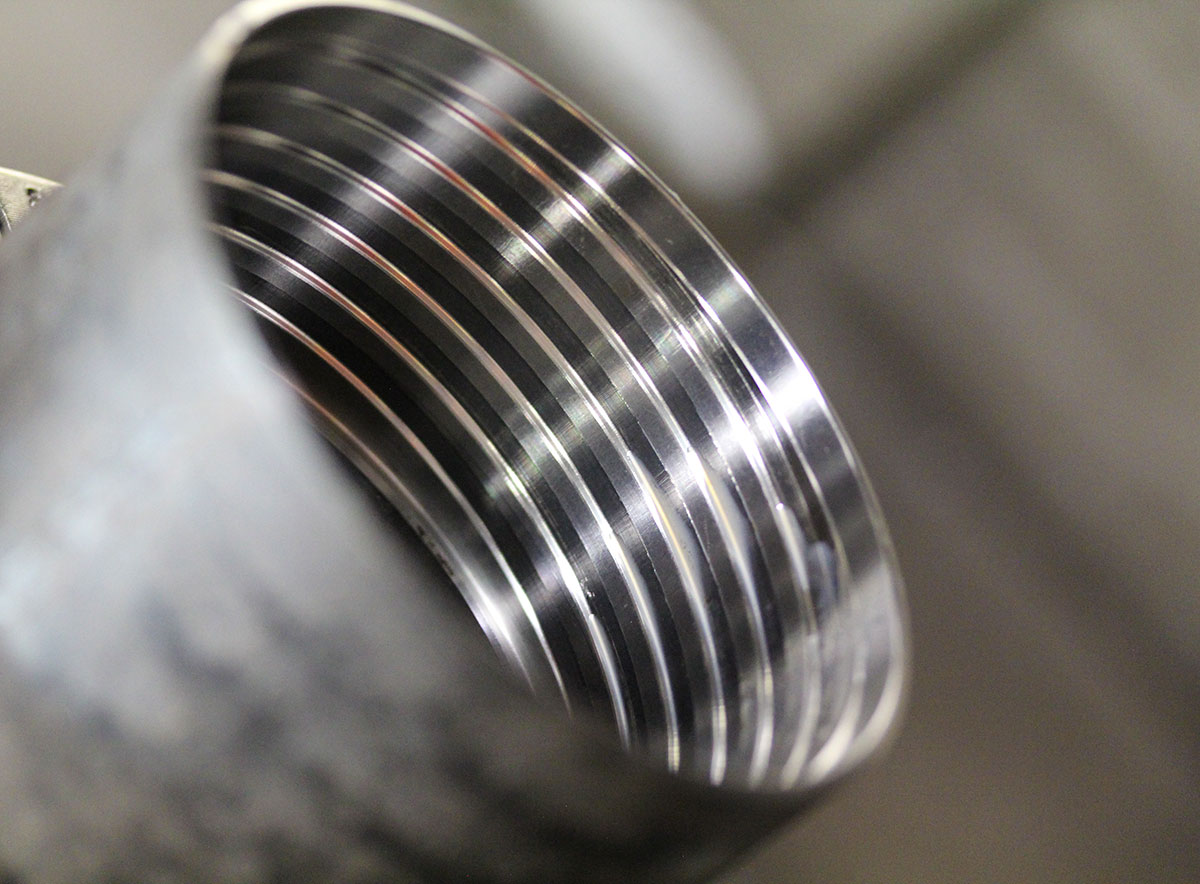

Tiges de carottage filaire XQ

Une combinaison unique d'un angle de flanc inversé autobloquant de -20 degrés sur les filetages et d'une répartition symétrique de la charge, associée au corps central à double recuit W-Wall ™, fait des tiges de carottage à câble XQ ™ l'une des plus profondes du marché. . XQ a un angle de flanc négatif accru de -20 degrés par rapport à -10 degrés pour les tiges RQ ™. L'augmentation de l'angle des flancs négatifs, combinée aux filetages à double démarrage, élimine presque le renflement du caisson et offre une plus grande résistance dans les applications à couple élevé.

Les articulations XQ brevetées ont des filetages à double début opposés qui s'alignent automatiquement, de sorte que l'accouplement s'engage en douceur. Ceci fournit une réponse de charge équilibrée et double la surface de contact, ce qui signifie la moitié de la pression de contact. Cette répartition symétrique de la charge augmente considérablement la capacité de charge pour des tiges plus fortes et plus profondes. Le train de tiges plus léger a augmenté la capacité de profondeur de la foreuse et réduit la fatigue des foreuses lors du déclenchement manuel. Le diamètre intérieur élargi a également considérablement réduit le temps de déclenchement du tube intérieur pour une productivité améliorée.

Les nouvelles tiges de carottage NXQ ™ et HXQ ™ W-Wall sont dotées d'un tube double en attente de brevet, avec la même réduction de poids global et une vitesse de déclenchement du câble supérieure à celle du V-Wall. Cependant, l’épaisseur de paroi standard au milieu de la tige XQ élimine l’usure prématurée au milieu du corps et résiste à la flexion, comme un tube à paroi droite.

Comme tous les tiges de carottage Boart Longyear, les tubes XQ W-Wall sont étirés à froid à partir d'acier allié nord-américain de haute qualité, uniquement traités selon les spécifications de Boart Longyear.

Bits Longyear

Boart Longyear a réussi à créer une liaison chimique entre le diamant et la matrice, qui est plus forte que le diamant lui-même. La projection de diamant accrue et le rinçage amélioré du visage créent un peu plus de polyvalence, des taux de pénétration plus élevés et une durée de vie plus longue. Les forets Longyear sont similaires aux gros forets diamantés, mais avec les caractéristiques de forage faciles et lisses, les foreurs préfèrent. Cela se traduit par une augmentation de la productivité tout au long de l'opération et, finalement, par un renforcement du noyau.

Pour supporter des taux de pénétration plus élevés, les nouvelles formules Longyear ™ sont combinées à une nouvelle géométrie, plus ouverte et plus expressive. Les voies navigables intermédiaires coniques améliorent le rinçage et empêchent l'accumulation de débris. Conçue pour une coupe rapide sur un sol compétent, la nouvelle géométrie express est disponible dans nos hauteurs de couronne de 16 mm pour maintenir la durée de vie du trépan à des vitesses de coupe plus élevées.

Les protubérances uniques Razorcut ™ sur la face du foret contiennent des diamants qui permettent au foret de commencer à couper dès la sortie de la boîte, même dans les terrains les plus mous. La disposition de ces protubérances améliore également le suivi et l'équilibre dans le trou au début du forage.

Permission de média: Si vous souhaitez republier cet article sur votre site web ou sur support papier, veuillez contacter marketing@boartlongyear.com pour permission. Nous sommes heureux que vous partagiez nos articles, et nous vous demandons seulement de citer Boart Longyear comme source et de fournir un lien, le cas échéant.