Features & Benefits of Longyear™ Diamond Bits

RAZORCUT™

Boart Longyear’s patented Razorcut™ protrusions on the face of the bit contain diamonds that enable the bit to begin cutting right out of the box, even in the softest ground. The arrangement of these protrusions also improves the tracking and balance in the hole when drilling begins.

LONGYEAR™ MATRIX

Boart Longyear successfully created a chemical bond between diamond and matrix, which acts stronger than the diamond itself. Thanks to this chemical bond diamonds are able to project farther above the matrix allowing for increased life, higher penetration rates, and improved face flushing with the easy, smooth drilling characteristics drillers prefer. This means increased productivity throughout the entire operation.

INNOVATIVE WATERWAY GEOMETRY

Our newest geometry, the tapered swirl (TSW) offers fast penetration in competent ground with the added ability to easily push cuttings in broken ground conditions to the OD thanks to the tapered design. This geometry is currently available in 20mm crown heights for extended life.

Durch die Entwicklung eines firmeneigenen Verfahrens zum Beschichten von Diamantmeißeln im Ofen hat Boart Longyear erfolgreich eine chemische Verbindung zwischen Diamant und Matrix hergestellt. Die Bindung wirkt stärker als der Diamant selbst und bietet eine höhere Projektion des Diamanten (bis zu 80% im Vergleich zu 40% für mechanisches Bonden) für ein verbessertes Spülen, höhere Durchdringungsraten und eine längere Standzeit.

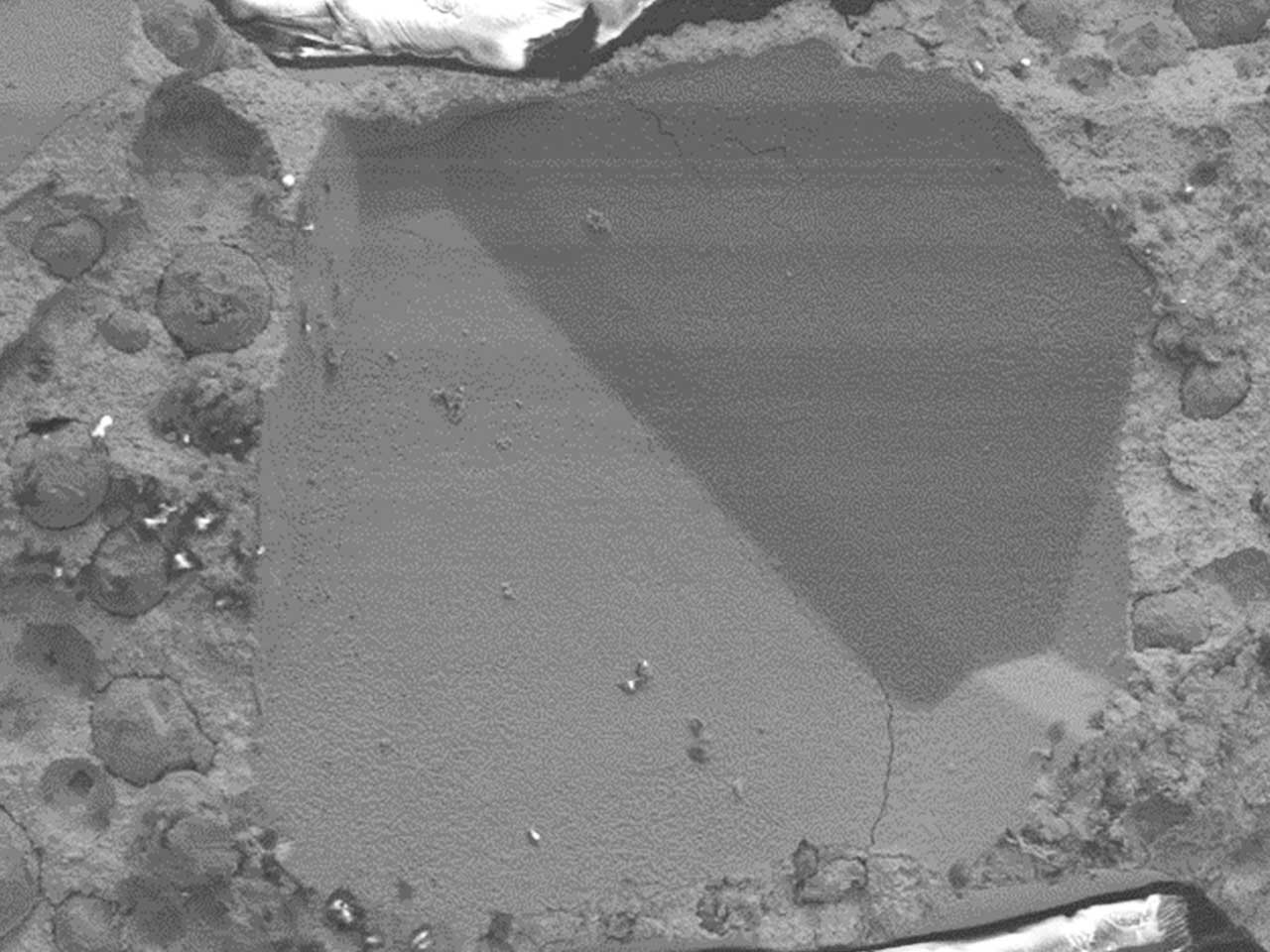

Typische Diamantüberzüge bilden aufgrund des starken Oxids auf typischen Titanüberzügen keine chemische Bindung, was zu einem 40% igen Diamantvorsprung führt wie das mechanische Bonden. Da ein Longyear-Bohrer bohrt und die Matrix am Boden abnutzt, bleibt der Diamant länger in Position und wirkt wie ein größerer Diamant, was zu mehr Metern pro Bit führt.

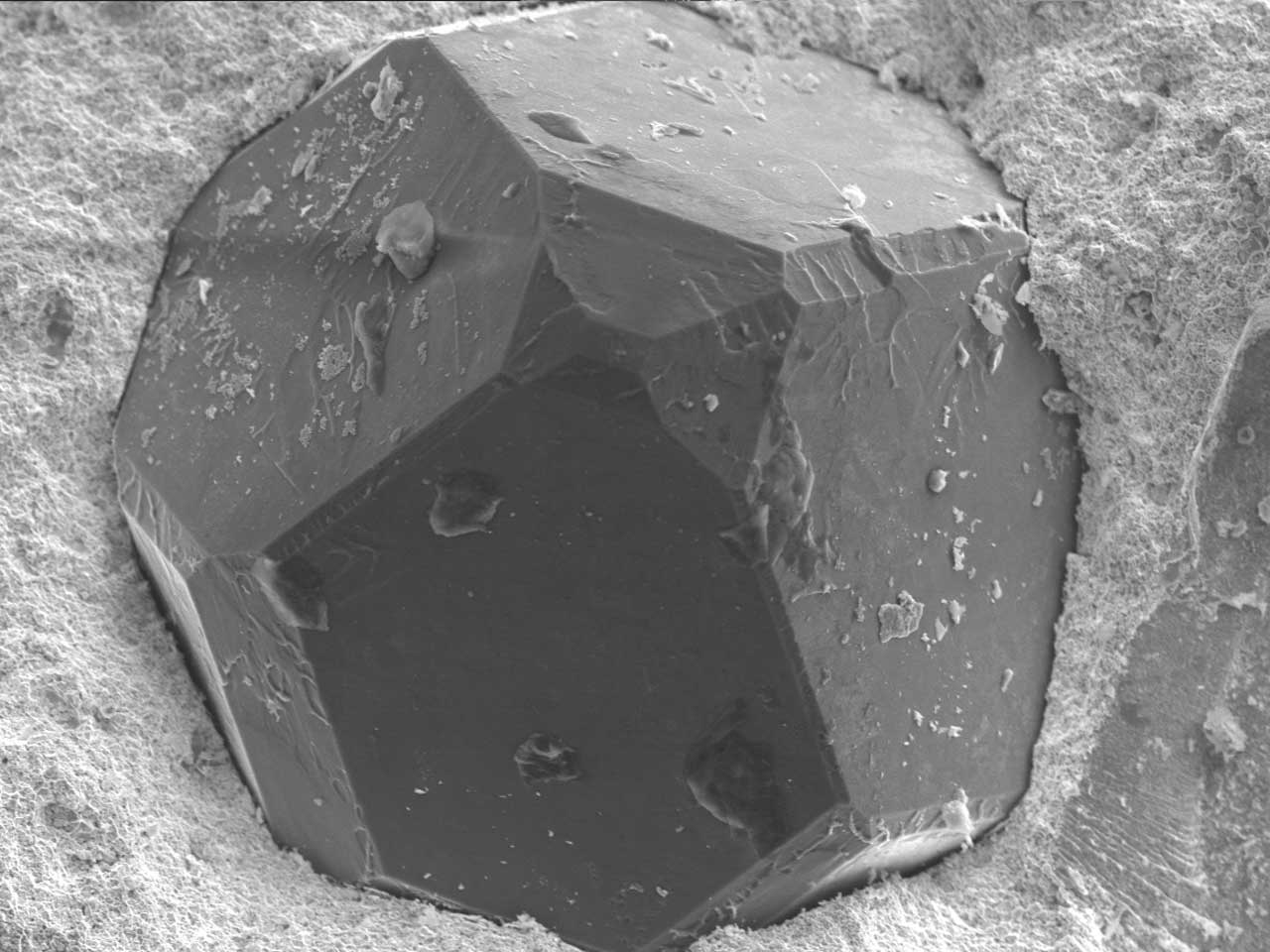

Oben: Spalt in mechanisch gebundenem Diamant

Above: no gap in Longyear™ Diamond Bit matrix

"Die neuen Longyear-Bits werden schneller geschnitten und halten länger. Diese beiden Qualitäten sind schwer zu finden. Normalerweise wird ein Bit, das schneller abschneidet, schneller aufgebraucht - was mehr Auslöser bedeutet, um das Bit zu wechseln. Die neuen Longyear-Bits scheinen zu wirken Sie haben die richtige Balance. Es ist wichtig, das richtige Gebiss für die Art des Gesteins auszuwählen. Langjährige Bohrer erleichtern dies. Ich empfehle die neuen Longyear-Bohrkronen sehr - sie haben die Durchdringungsraten, die Produktivität verbessert und überlegen gebraucht."

- Robert Jex, Abteilungsleiter der US North Coring

"Die Longyear-Bits durchdringen den Rock nicht nur schneller, sie halten auch weit über die anderen Diamant-Bits hinaus, die ich in meiner 32-jährigen Karriere verwendet habe."

- Mike Reedy, Bereichsleiter, DS - Southwest Coring