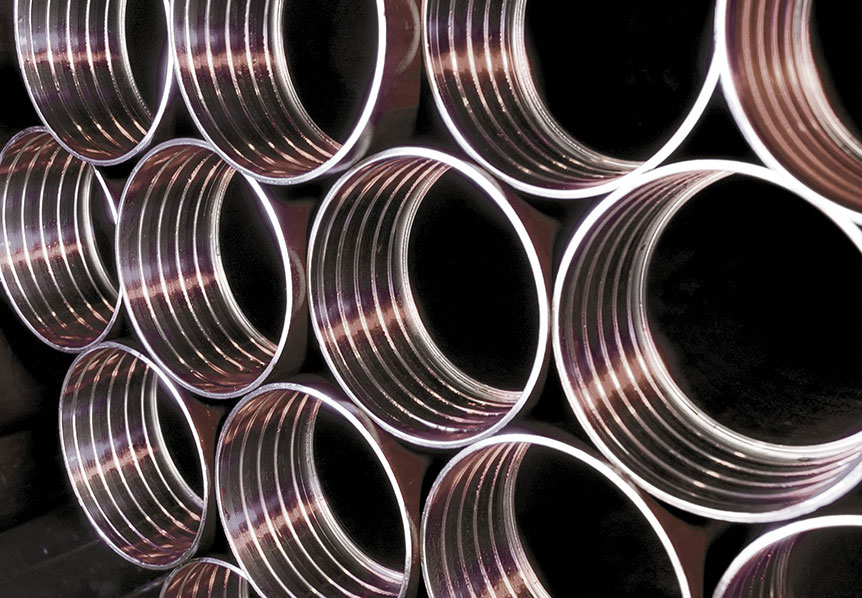

RQ® Rods and Tubing

TUBING

Hochwertige Rohre aus legiertem Stahl. Konsequente Konzentrizität, Geradheit und Wärmebehandlung.

FADEN

Coarse RQ threads (3 threads per inch) with increased taper, provide easier make and break as well as anti-jamming. Finer RQ™TK threads provide high performance for Thin Kerf wireline systems. Load efficiency of 50% provides ultimate strength for demanding applications.

THRU-WALL-WÄRMEBEHANDLUNG

Bietet eine Materialstärke von 175%. Hitzebehandelte Kastenenden erhöhen die Materialfestigkeit und die Lebensdauer des Fadens erheblich.

EINSATZHÄRTEN

Boart Longyear ist der einzige große Hersteller der Branche, der Gewinde einsatzgehärtet.

Bedeutende Forschungs-, Entwicklungs- und Feldtests haben zu einem Härtungsprozess geführt, der seinesgleichen sucht.

Der Gewindezapfen des Stifts ist auf einen Nennwert von 60 HRC gehärtet, um eine Beschädigung der Adhäsion zu vermeiden.

Beseitigt die Übertragung von Verschleißmaterial zwischen Fäden gleicher Härte, was zu großflächigem Verschleiß und Gelenkverstümmelung führt.

OPTION: W-Wand

W-Wall™ is an internally-upset rod available with our high load-efficiency patented RQ™ thread or HD thread. W-Wall rods undergo our unique combination of heat treatment processes for performance in demanding applications.

W-Wall™ for Increased Productivity and Reduced Costs

Mit bis zu 30% weniger Gewicht im Bohrstrang erhöht sich die Produktivität bei gleichzeitiger Senkung der Gesamtbetriebskosten.

W-Wandstangen:

Reduzieren Sie die Ermüdung des Bedieners beim Rutenhandling und erhöhen Sie damit Sicherheit und Produktivität.

Reduzieren Sie die Treibstoffkosten beim Transport von Stangen und erhöhen Sie die Kraftstoffeffizienz der einzelnen Bohrinseln vor Ort.

Erhöhen Sie die Nenntiefenkapazität des Bohrers. Ein Bohrgerät mit einer Nennleistung von 2500 m HRQ kann beispielsweise einen W-Wall-Bohrstrang mit 3000 m HRQ bewältigen.

Erhöhen Sie die Flexibilität in der Mitte des Körpers, was bei Keil- oder Lenkanwendungen von Vorteil ist, aber die Steifigkeit des Bohrstrangs während des Bohrvorgangs nicht verringert.

Was macht die RQ-Ruten von Boart Longyear zu den besten auf dem Markt?