COMPACT AND MOBILE

Ideal for narrow-vein applications. With a small footprint and tramming capability, the StopeMaster is compact enough for cage transport, level-to-level mobility and optimum maneuverability in confined areas.

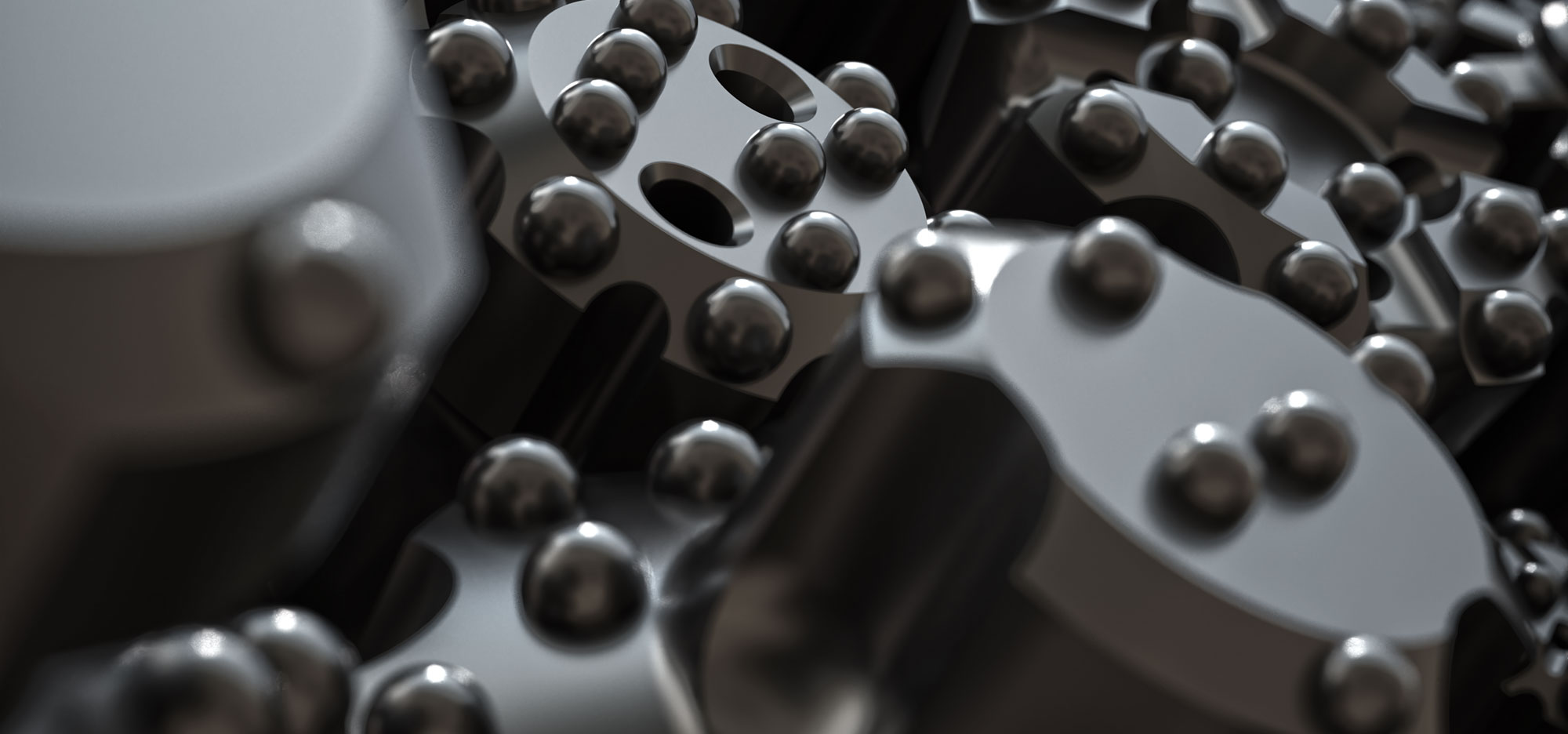

HIGH PERFORMANCE

Utilizes a proven hydraulic rock drill for high productivity and deep accuracy. Incorporates the Hercules Rod Mate Centralizer for positive centering and simple operation.

MODULAR

Efficient dismantling and re-assembly enables faster move times and increased productivity.

ACCURACY AND FLEXIBILITY

The Helac Positioning System provides full 360° radius drilling with extreme accuracy. Capable of parallel drilling, ring drilling, service holes, drop raises, and cable bolting. Uses dual in-line hydraulic feed cylinders to provide balanced thrust to the drill string center.

VERSATILE

Capable of more drilling patterns than any other platform on the market. Pivoting traverse feature allows straight, accurate drilling. Hydraulic rotation of rock drill carriage adds further flexibility of drilling patterns.

Features

Designed to bring maximum benefits in a compact, mobile package.

Modular design with efficient dismantling and reassembly. The StopeMaster can be transported rapidly, even into captive areas, decreasing move time and increasing productivity.

Excellent deep hole accuracy, through the superior guidance of the durable feed system and Hercules centralizer.

Consistent, high performance regardless of varying operator skill levels or conditions.

Increased availability since routine maintenance can be done at the face, by operators without specialized training.

Longer intervals between scheduled preventative maintenance servicing, proven through millions of feet of drilling experience.

| Drilling Depth Guidelines | ||

| Rock Drill | HD 155 Hydraulic Rock Drill | |

| Carrier | 4 wheel Skid Steer carrier | |

| Up to 30% gradeability | ||

| 4 wheel independent drive and braking (SAHR) system | ||

| Drill Positioner | Traverse side to side travel of 1.5 m (60 in.) | |

| Traverse movement via dual opposed hydraulic cylinders | ||

| Dual motor/planetary drive system coupled with SAHR braking system | ||

| Independent feed crowd | ||

| Options | 0.9 m, and 1.2 m, and 1.83 Traverse widths | |

| Laser hold alignment system | ||

| ITH conversion package | ||

| Dimensions | Overall weight is 13,742 kg (8,250 lbs) | |

| Raise transport - Powerpack (largest module) Length 2570 mm, Width 1320 mm, Height 1220 mm | ||

| Cage Transport - Length 4010 mm, Width 1370 mm, Height 1800 mm @ 5230 kgs | ||

| Drilling Depth Guidelines | ||

|

Rock Drill HD 155 Hydraulic Rock Drill |

||

|

Carrier 4 wheel Skid Steer carrier Up to 30% gradeability 4 wheel independent drive and braking (SAHR) system |

||

|

Drill Positioner Traverse side to side travel of 1.5 m (60 in.) Traverse movement via dual opposed hydraulic cylinders Dual motor/planetary drive system coupled with SAHR braking system Independent feed crowd |

||

|

Options 0.9 m, and 1.2 m, and 1.83 Traverse widths Laser hold alignment system ITH conversion package |

||

|

Dimensions Overall weight is 13,742 kg (8,250 lbs) Raise transport - Powerpack (largest module) Length 2570 mm, Width 1320 mm, Height 1220 mm Cage Transport - Length 4010 mm, Width 1370 mm, Height 1800 mm @ 5230 kgs |

||