PRODUCTIVE

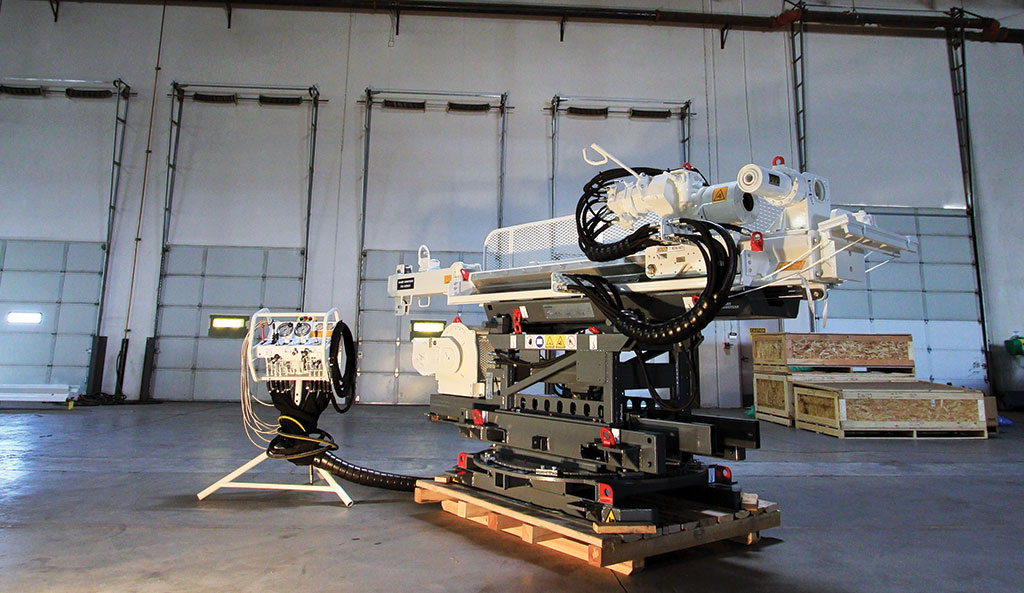

The LM75 drill provides high pullback force and a fast rod handling rate. The feed frame is available in two sizes to suit a variety of operating conditions.

RELIABLE

The LM75 features a load sensing hydraulic system, proportional controls, a fail-safe rod clamp, built in troubleshooting and a spooling device. These features make the LM75 a highly reliable drill when drilling in harsh conditions.

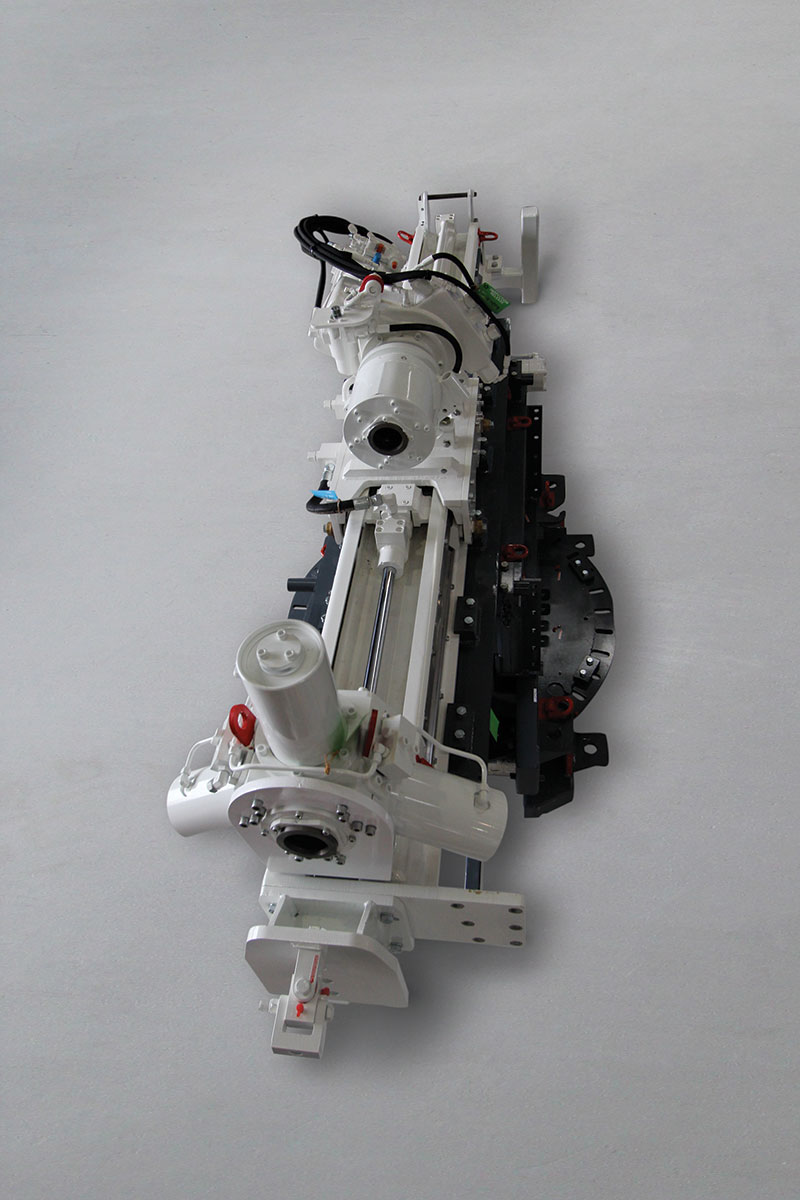

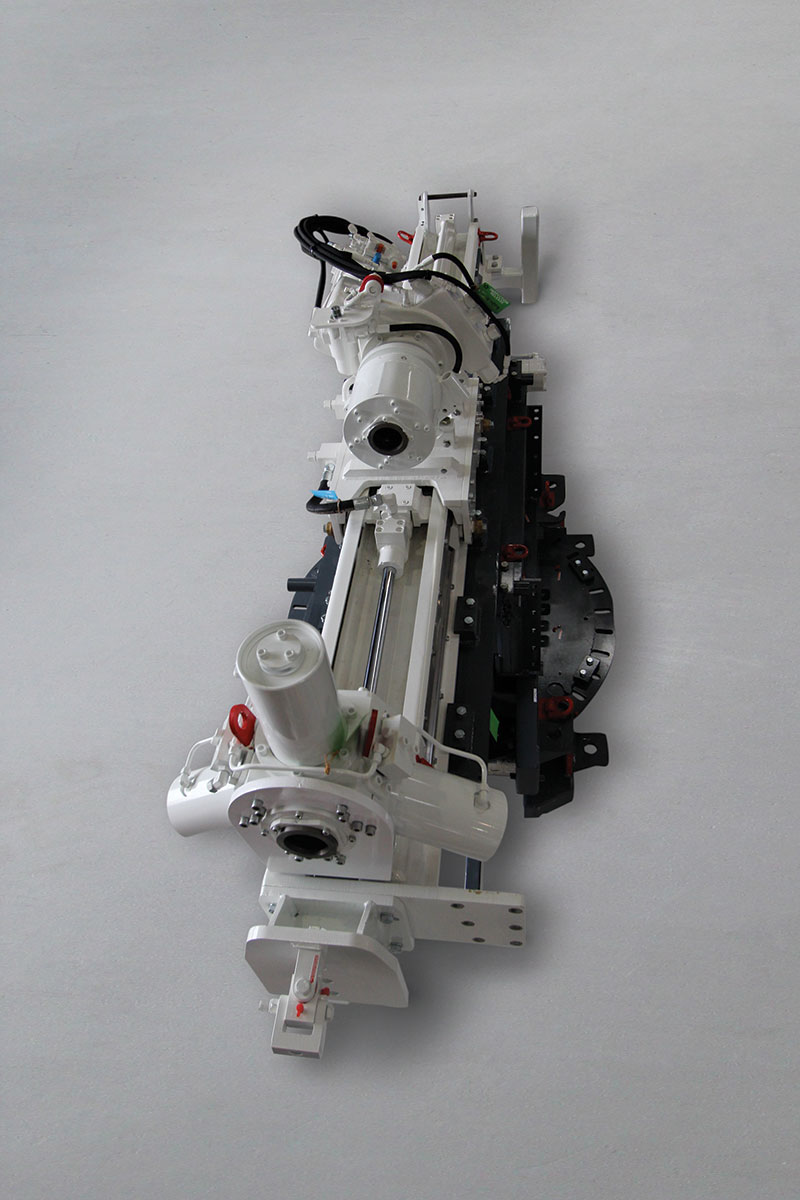

MODULAR DESIGN

The LM75 was designed as a modular drill rig with a number of options for site-specific customization. This drill is easy to operate and upgrade to meet the needs of future drilling projects.

SAFE

An optional patented rod handler can be added to the LM75, which greatly increases driller safety. The rod handler makes loading rods easier and ensures they remain away from moving parts during rod tripping.

DRILLING APPLICATION

The LM75 is capable of both wireline and conventional coring.

Features

1. LOAD SENSING HYDRAULICS

Load sensing hydraulics maximize efficiency and reduce heat.

2. PROPORTIONAL CONTROLS

Proportional controls and lock levers provide optimum control of rpm and feed.

3. HIGH TORQUE BREAKOUT

Automated high torque break out device breaks most rod joints automatically.

4. FAIL SAFE ROD CLAMP

Hydraulic open and spring close rod clamp results in fail safe operation.

5. DIRECT COUPLED FEED FRAME

Direct coupled feed frame results in lower maintenance and smoother feed transmission.

6. SEMI-AUTOMATED ROD HANDLING (OPTIONAL)

Semi-automated rod handler (optional) makes handling of rods safer and easier.

7. ELECTRONIC CONTROLS UPGRADABLE (Optional DCi)

Upgrade the controls system with the DCi for improved safety and productivity. The DCi offers unattended drilling and semi-automated functions and operates both the rod handler and drill from a single control panel.

| Specification | Metric | U.S. |

| Vertical Depth Capacity (700FF) | 850 m (NRQ) | 2,800 ft (NRQ) |

| Drill Rod Size | AQ to HQ | |

| Feed Force | 53.9 kN | 12,080 lb |

| Pull Force | 81.4 kN | 18,250 lb |

| Feed Length | 1.8 m | 6 ft |

| Head Torque | 325 N-m @ 1,250 RPM 900 N-m @ 500 RPM |

329 ft-lb @ 1,250 RPM 662 ft-lb @ 500 RPM |

| Electric Motor | 75 kW | 101 hp |