BITS & RODS

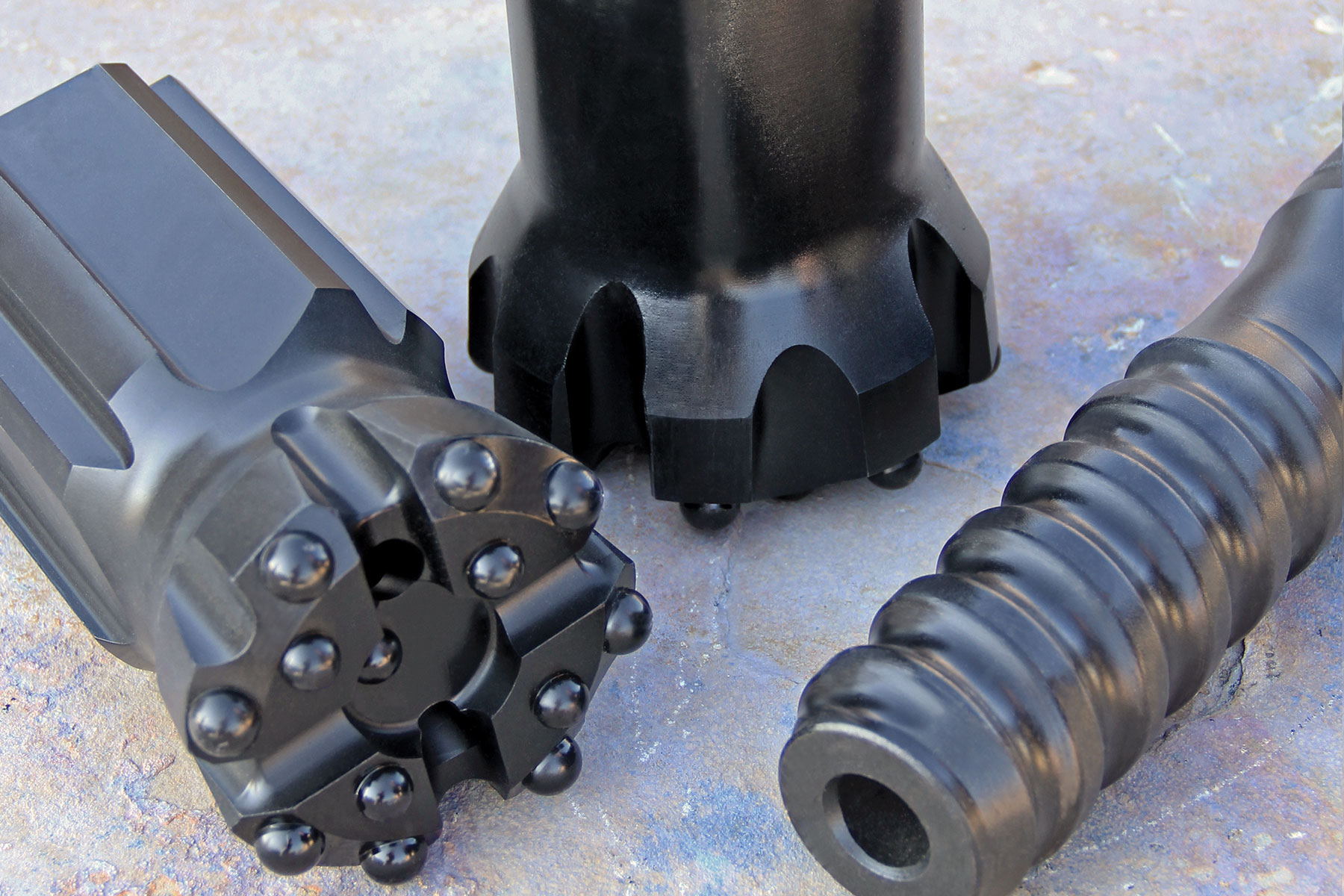

Boart Longyear’s bits and reamers feature carbide inserts manufactured for maximum strength, toughness and wear resistance. Available in standard hemispherical, parabolic, conical, and ballistic profiles.

High grade, heat treated steel bit bodies available in standard, retrac and straightrac design configurations.

The insert and steel combinations result is a diverse product offering delivering high penetration rates, low hole deviation, extended life, and increased productivity.

Reamers are available with patent-pending high productivity back cutting features.

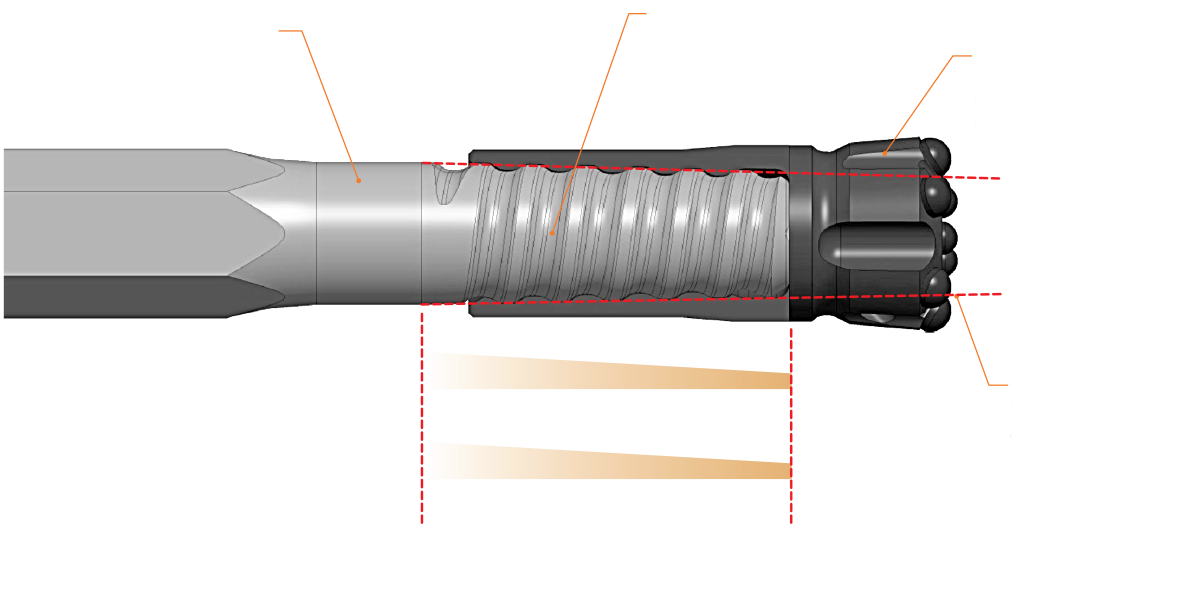

IMPAKT™

RACEWAY TECHNOLOGY

After development and global 3rd-party testing, the IMPAKT design innovation has been proven to actively clear cuttings from the entire cutting face. With flushing speeds increased by 25%, the resulting penetration rate has been improved by an average of 18%.

DRIFTMASTER

Optimized strength, fatigue resistance, and wear life.

DRIFTMASTER THREADS REDUCE STRESS FOR EXTENDED LIFE

The tapered thread profile provides a larger cross-section at the high-stress location (more steel where it is needed)

The unique thread profile further reduces the thread root stress compared to standard designs.

A +25% reduction in applied stress leads to an exponential increase in the fatigue life offered by DM28 and DM35.

Shanks

Made from high-quality steel, Boart Longyear shanks are manufactured to provide optimal wear resistance, strength, and toughness to provide maximum energy transfer from the hammer to the drill string.

We carry a wide variety of products that provide compatibility with most standard hydraulic, pneumatic hammers.

Custom products are available upon request.

Male Shank Adapters

Generally better suited for drifting, tunneling and extension applications where high bending stresses are present.

Female Shank Adapters

Used when the drilling space is limited and the total feed length is important (i.e., underground roof bolting).

Accessories

Full range of accessories are available to maintain a high level of productivity:

- Bit adapters

- Guide adapters

- Split set drivers

- Nut drivers

- Adapter couplings

- Recovery tools