SAFETY INNOVATION

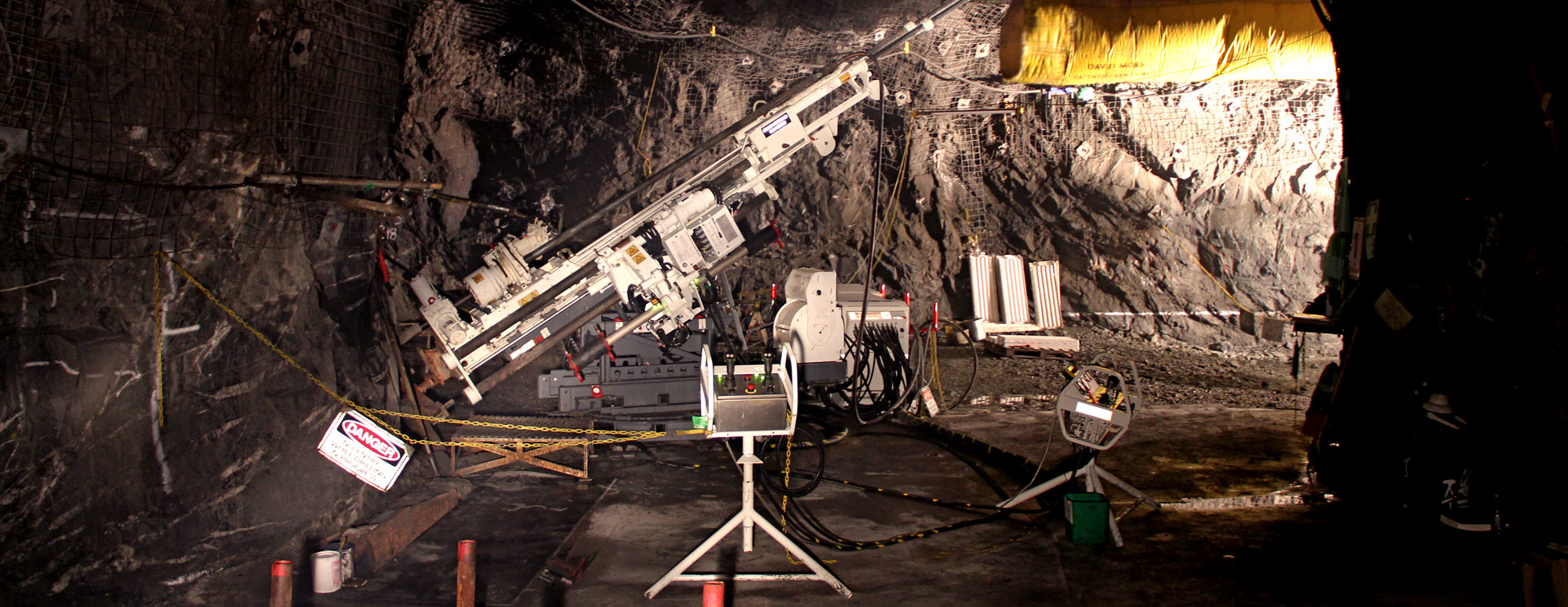

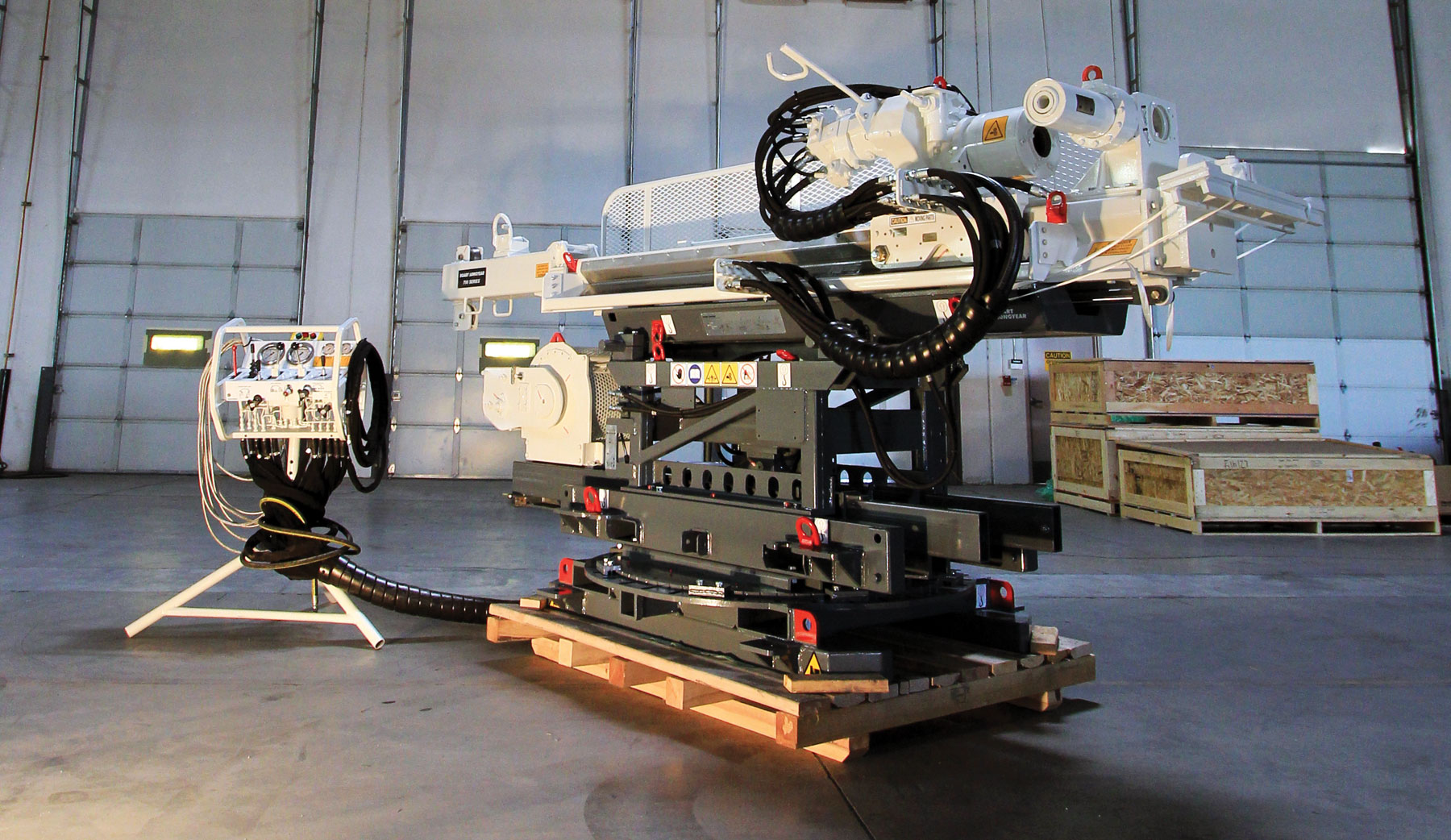

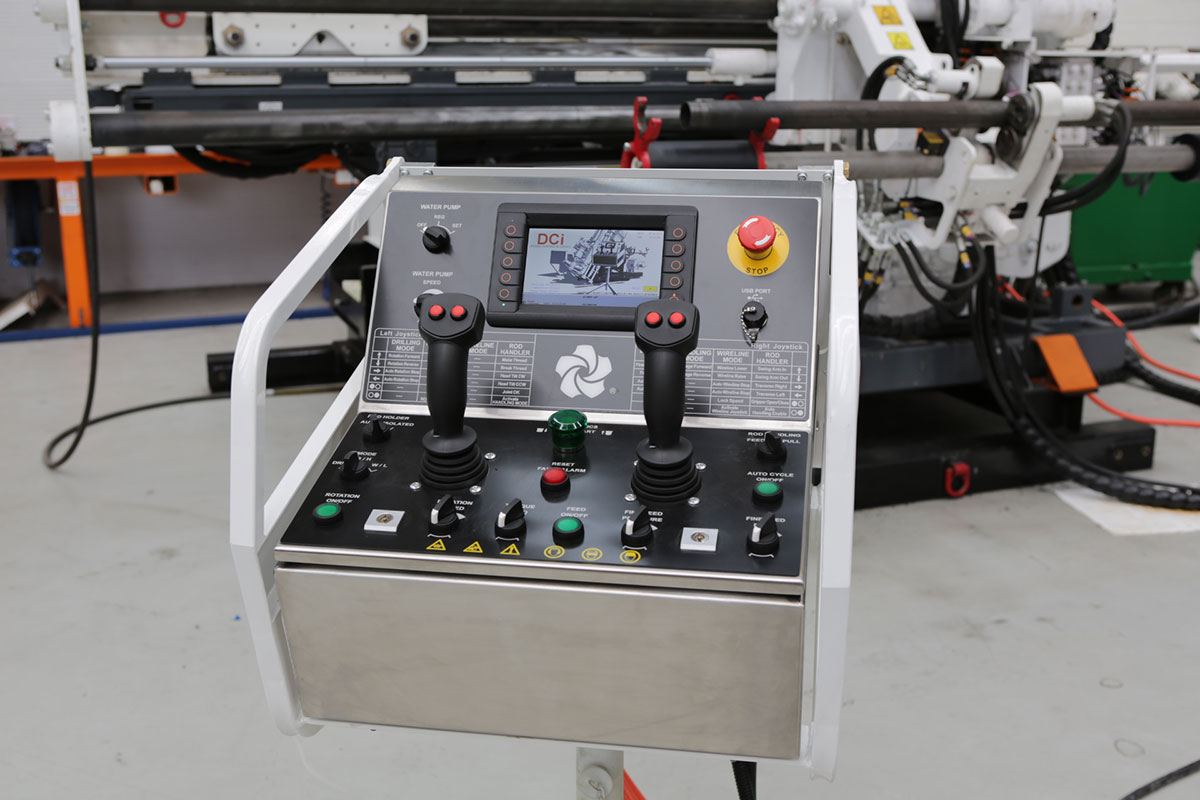

The DCi is a considerable step forward for increasing safety onsite by moving the driller away from hydraulic hoses – isolating the driller from this hazard. The DCi control panel is lightweight and portable offering a distinct advantage over heavier hydraulic control panels for rig moves.

REAL-TIME INFORMATION

Complete control system integration and sensors provide immediate feedback of drilling conditions and records both event and drilling conditions data for reporting and analysis and is downloadable to a USB. Sensors provide real-time status display on rotation speed and pressure, feed and holdback pressure, water flow and pressure, penetration rate, bit force, diagnostics, and alarms. Both imperial and/or metric units can be selected for display.

UNATTENDED DRILLING

The DCi facilitates unattended drilling, allowing the rig to complete a rod run letting drillers complete a shift change, take a meal break, or catch up on other tasks. The driller sets up operating parameters and a laser beam near the drill and the DCi will automatically shut down drilling if either the drilling condition parameters or the laser beam is breached. Because the DCi has the capability to set up drilling condition parameters, this also allows supervisors to set up parameters for less experienced drillers.

ONE TOUCH DRILLING

Once drilling has commenced, with the push of a single button on the DCi control panel, the control system monitors drill rod position, rotation speed and feed, and continues drilling. This sequence includes a re-chucking process to feed the entire rod. On completion, the control system disables rotation and allows for a short period of water flushing before shutting down. Additionally, one touch rod feed and pull functionality allows the driller to efficiently and effortlessly trip rods.

CONVENTIONAL OR WIRELINE

The DCi works with conventional drilling and wireline methods and the rig is equipped with 600 m (1,969 ft.) of 6 mm wireline cable. For wireline drilling, a wireline drum counter has been incorporated into the DCi for semi-automatic descent and retrieval of the wireline. While attention must be paid when sending or retrieving wireline and tooling, the driller is no longer required to keep his finger on the button or hold a lever when retrieving core.

Drill Control Interface - DCi

Features

Increase safety by isolating the operator and controlling the rig and rod handler.

Increase productivity with auto-drilling features and immediate feedback on drilling conditions and penetration rates for adjustments to weight-on-bit.

Win projects based on the versatility for wireline or conventional core retrieval.

DOWNLOAD FULL SPECIFICATIONS (XLS)