NON-MINING

April 28, 2020

Contractor getting the edge

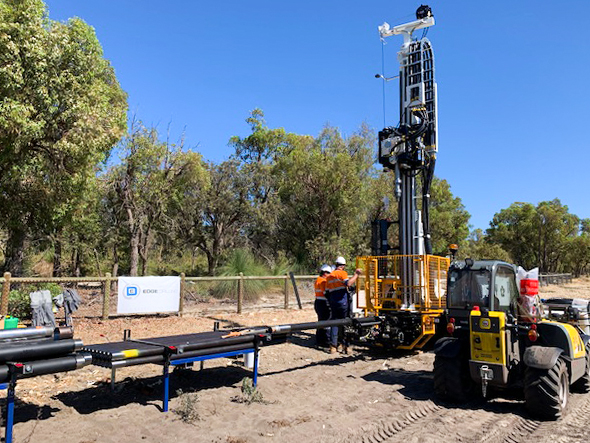

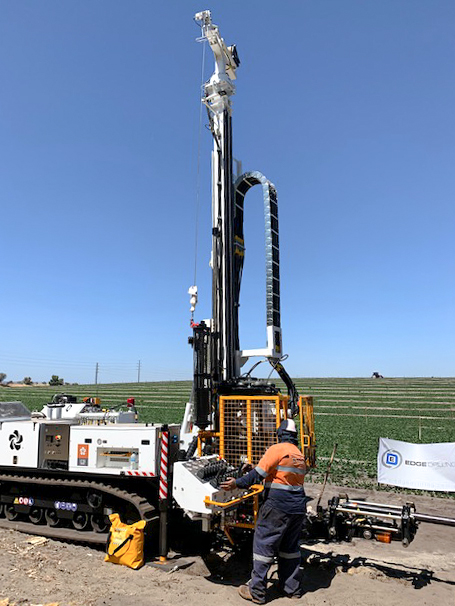

Perth-based environmental and geotechnical drilling contractor Edge Drilling is growing in leaps and bounds, purchasing a string of new rigs including its first sonic rig.

Edge Drilling director, John Argiropoulos, recently took delivery of a Boart Longyear LS™250 MiniSonic™ rig that is suited to a variety of soft ground, shallow drilling projects including environmental, tunneling, water management, grade control, leach pads, and tailings dams.

The rig delivers faster penetration for nearly undisturbed samples using little or no fluids, said John, and its casing system makes it ideal for a variety of applications including mining, environmental, and infrastructure projects.

“I've been looking at getting into this type of drilling from the first time I saw it."

The rig provides extremely accurate sampling for unconsolidated formations which makes it suited to mining, but it also eliminates the risk of cross contamination making it ideal for environmental and geotechnical work. It can also precisely drill straight holes at varying angles which ticks the box for infrastructure projects.

“We've already got five months of work lined up with the rig," John told Australasian Drilling.

The idea of acquiring a sonic rig first came to John during a visit to Christchurch in New Zealand where he saw the rigs undertaking post-earthquake recovery sampling work.

“I've been looking at getting into this type of drilling from the first time I saw it,” he said.

“After the earthquake in Christchurch, I saw massive advantages with sonic rigs in drilling overburden and getting near on 100 percent recovery sampling. The rigs were drilling every house in carports or garages and were looking for signs of liquefaction.”

Liquefaction is where the strength and stiffness of soil is reduced by earthquake shaking. If liquefaction was found following testing in Christchurch, the dwelling would be demolished.

“They had conventional rigs at the start including standard diamond drilling, but they weren't getting any core recovery, being glacial fill," John said. "However, the sonic rigs collected everything from pebbles and cobbles, to rock, clay, silt and sand. They were very impressive.”

With work increasing, John eventually took the plunge and invested in a sonic rig.

“We're getting much busier,” he said. “In the space of 12 months, we've gone from two rigs at the start of last year to seven rigs now. We've expanded quite a lot.”

John said work began to resurge since 2016. A big push by Main Roads WA (Western Australia) for testing bridges across the state is creating work from the rollout of the government's METRONET program and is expected to generate more construction activity and geotechnical work in the near future. The METRONET program is one of the largest single investments in public transport that Perth has seen and will involve about 72 km of new passenger rail and up to 18 new stations.

With enhanced capabilities thanks to the new rigs, John is upbeat in his outlook for the business. However, like most contractors, he is feeling the pain of skill shortages. John said he is managing the issue through in-house training.

"I'm a firm believer of training in-house as the best way forward because we can train personnel according to our standards, expectations, policies, and procedures.”

Originally published in Australasian Drilling Magazine, February/March 2020

SIGN UP FOR THE INSITE DIGEST

Sign up for the INSITE Digest to receive articles like this and more.