Truscan™

In-field assays, wet and dry, chips and core

An in-field drill sample scanning system that provides assays on the day with near-real-time photos and geochemistry. Standardizing sample imagery and removing subjectivity.

Ensuring assays that aren't just faster, better and cheaper, but also set a foundation for a digital future.

ACCURATE SAMPLE SCANNING

TruScan™ offers explorers and mine geologists non-destructive and accurate elemental data right there in the field.

• Non-destructive, accurate, elemental data

• Standardising scanning ready for data science

• High-resolution photography

• 20mm increments

• Chips and core, wet and dry.

IN-FIELD SAMPLING

TruScan™ measures the rock directly in the field eliminating sub-sampling or preparation. Improving chain of custody and reducing lab assays to QA/QC checks. TruScan™ is designed to fit within the normal workflow of drilling crews, and data is constantly being transferred to secure cloud storage.

Capable of scanning 80 to 100 m (200 to 300 ft) of core per 12-hour shift (depending on required data density) and many more meters (feet) per shift on RC chips, a single unit can potentially scan the core from multiple drill rigs, legacy core, or a combination of both.

PREPARED FOR

PRE-CONCENTRATION

With assay increments as small as 20mm, pod sizes for block models can reduce and the feasibility of pre-concentration and be explored in greater detail with a greater likelihood of success.

Increase the value of your projects.

CONTROLLED

CHAIN-OF-CUSTODY

Reducing manual handling, hand-overs and third-party involvement reduces the likelihood of sample error and increases the data sampling controls on-site.

Reduce lab assays to QA/QC checks.

STANDARDIZED

SAMPLING

By creating a controlled environment for sample scanning and photography TruScan collects data efficiently and on the same basis.

Improving orebody data science and insights

SAFETY & EMISSIONS:

Lab assays require core to be cut, bagged and shipped off site. TruScan™ analyses material while it’s still in the core tray, removing manual core handling and therefore reducing the likelihood of repetitive strain injuries. Drilling campaigns can also avoid significant emissions by reducing lab freight to only QA/QC checks. Permanently removing (up to) thousands of tonnes of freight in core sample deliveries to labs. Helping geology teams contribute to their assets emissions targets.

CLOUD-CONNECTED

TruScan™ makes its information available in the cloud to your experts all over the world.

Leverage global expertise from anywhere in near real time; giving teams access to drill data faster, at a higher definition, with lower sampling error, ready for machine learning. With the assistance of powerful analytics, data can be quickly interrogated to deliver geological insights including lithological and structural information.

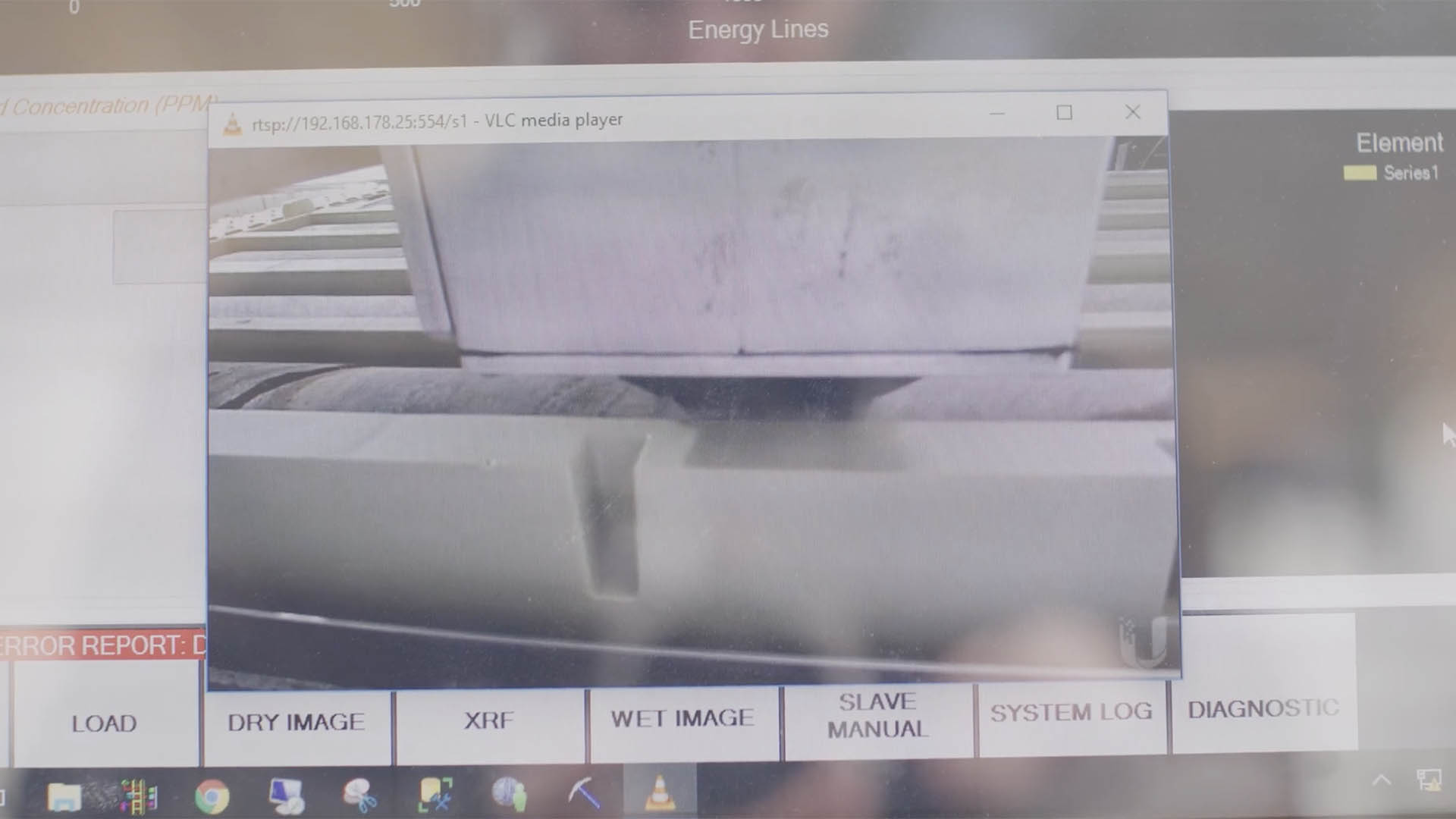

Mine Spec Trailer

This go-anywhere trailer is mine-spec and purpose-built to operate in all conditions. All features are controlled, automated and repeatable; a process that improves speed and accuracy by removing sampling errors, while lowering costs associated with logging and analysis. A combination of mine-spec hardware and software, TruScan™ delivers XRF geochemistry and standardised high-resolution photography in increments as small as 20mm. Redefining high-definition assays for studies and block models.

Ready to add TruScan to your project?

Interested in TruScan? Submit a Request for Tender to include GDS technologies in your project.

REQUEST FOR TENDER

[pardot-form height="850" id="1557" title="Request for Tender"]